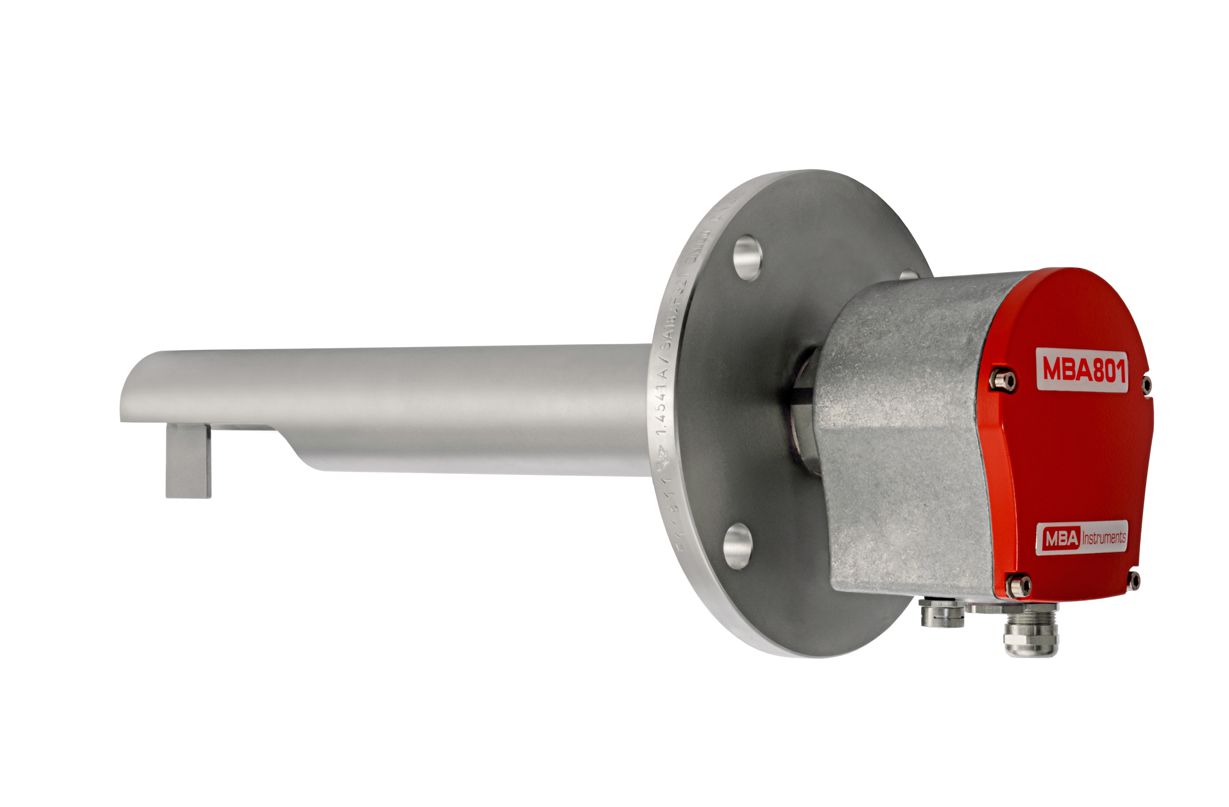

Propeller sensors MBA801 Halfpipe

Sensor with protective halved tube

Short movement of the impeller blade

Also optimal for conveyor overflows

Advantages

Impeller movement only 120 °

Special flange without the need for a protective roof

Also optimal for conveyor overflows

Robust design

Standard sensor head

Explosion protection

ATEX certified

The new and digital semi-rotating impeller sensor - MBA801 Halfpipe - measures directly in the flow of bulk material. The extra strong shaft (12 mm shaft diameter) is mounted on a tightly welded blade under the protective cover, which perfectly protects it from heavy or abrasive bulk material. The impeller rotates 120 degrees alternately under the protective cover.

Alternating rotation prevents the material from wrapping around the shaft or vane and does not cause incorrect detections. The double seal system protects the electronics against the ingress of dust and moisture.

If the bulk material rises in the silo and blocks the oscillation of the blade, an electronic signal is issued.

Halfpipe is used in places where measurement has not yet been possible.

With ATEX certification, level measuring devices are well equipped for zones prone to dust explosion.

Basic parameters for applications:

- bulk material such as PP and PE granules, polystyrene, grain, flour, dust, lime, etc.

- drive ambient temperature -50 ° C to + 60 ° C (without ATEX)

- drive ambient temperature for ATEX -20 ° C to + 50 ° C

- temperature in force up to 1200 ° C

- tank pressure -0.5 bar to +10.0 bar

- standard IP 65 protection

- power supply 24VDC or 115-230VAC